In the world of architectural design, the choice of cladding material is more than just a practical decision—it’s an opportunity to create spaces that resonate with harmony, emotions, and visual appeal. We understand the profound impact that colors, shades, and tones can have on the overall ambiance of a project. Our Sylva™ products embody this philosophy, offering a diverse palette designed to enhance both exterior and interior spaces.

A Spectrum of Possibilities

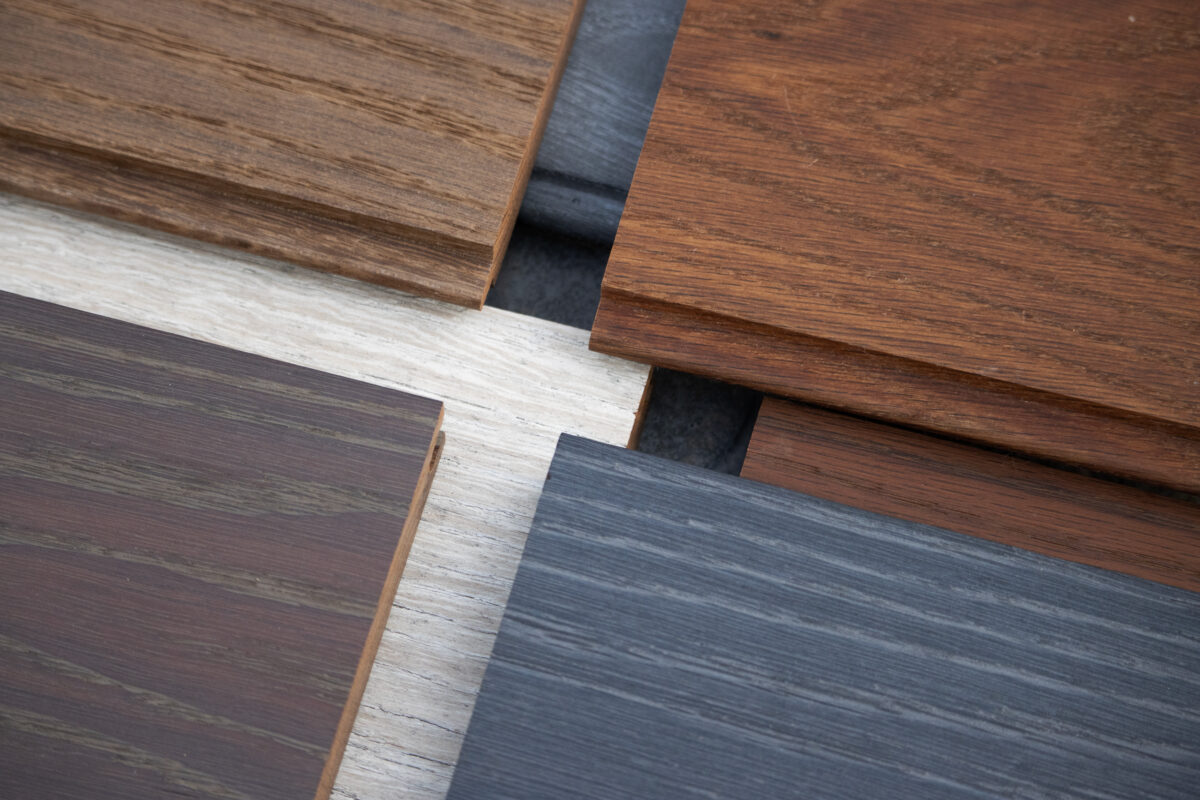

The Sylva collection features thermally modified red oak products, each showcasing a range of colors from rich browns and cool grays to the dramatic Shou Sugi Ban charred technique. The red oak base, treated through thermal modification, provides a versatile foundation that allows for a variety of finishes. Whether you’re designing a modern urban façade or a cozy interior retreat, there’s a Sylva product to meet all your aesthetic needs.

Introducing New Finishes

We’re excited to introduce eight new finishes—HAMERS, MICHAUX, TUSCA, SPROUL, PINCHOT, ROTHROCK, SINNEN, and TIA—that further elevate Sylva’s design potential. These new products are a result of innovative, aggressive surface brushing and proprietary finishes that enhance the natural grain and fully saturate the wood for a rich color that weathers beautifully over time.

The Influence of Color and Tone

Colors and tones are not just visual elements; they play a significant role in shaping the emotional and psychological experience of a space. Here’s how different shades of our new Sylva products can influence feelings and perceptions:

HAMERS features a bold, espresso-brown with cool black undertones that offer a grounded, natural appearance. It’s aggressive brush texture creates a depth that enhances its deep hue for a sense of sophistication for both contemporary and rustic spaces.

MICHAUX offers a blend of rich, deep browns enriched with vibrant red undertones for a dynamic, expressive finish. The warm coloration subtly shifts with the light, adding a depth and energy that’s perfect for both indoor and outdoor spaces.

TUSCA enhances the natural appearance and dramatic grain pattern inherent to red oak. The coppery-red undertones and natural brown hues offer the timeless, biophilic appeal of natural wood with added depth and dimension from the aggressive brush texture.

SPROUL is a dynamic finish that can range from red to deep maroon undertones depending on the character of the original wood. This rich, warm, and complex palette brings visual movement and character to a space, offering stunning detail that fits into any architectural and design style.

PINCHOT’s slivery-gray brings a natural, weathered elegance. The deep texture allows the finish to fully saturate the wood, offering a depth and dimension that weathers consistently over time, for designs that feel luxurious, calm, and spacious.

ROTHROCK is a balanced blend of medium to dark blue-gray tones with subtle, natural-wood highlights that shift in the light. Ideal for high-end interiors and minimalist spaces, it perfectly blends modern and clean design aesthetics with depth and dimension.

SINNEN features a striking, deep blue-gray for a dramatic, yet refined presence. The rich, saturated color gives the surface a cool, modern edge with subtle variations in tone that enhance the grain depth and add visual intrigue.

TIA delivers a dramatic, black finish that reflects natural light with subtle flashes of silver. Bold and modern, it offers a commanding presence that brings drama and intrigue to modern, minimalist, and contemporary spaces.

The expanded Sylva line of products offers a rich array of 21 different colors, tones, and textures designed to enhance and unify both interior and exterior spaces. By understanding the psychological impact of these shades and selecting the right tones, architects, builders, and designers can create environments that are visually appealing and emotionally resonant.

To experience the full range of Sylva’s color palette and textures firsthand, we encourage you to order samples. Holding the material in your hands allows you to truly appreciate the quality and craftsmanship of our products. Request samples or contact us to work with a Specification Consultant who can assist you in finding the perfect match for your next project.