Whether you’re working on a commercial or residential project, stairs are likely essential to the design. The initial step to obtaining a perfect stair package involves designing and requesting a quote, which can be an unfamiliar realm for many people.

Stair packages are pre-designed stair systems with all the necessary components to build a staircase. When searching for a stair package, it is imperative to understand the different types of packages available and the elements that make up a stair package.

Stair packages can be categorized into two main types: pre-manufactured and custom-built. Pre-manufactured stair packages are pre-designed and pre-built and are often less expensive than custom-built packages. They come in standard sizes and designs and can be easily installed by a professional. On the other hand, custom-built stair packages are designed and built specifically for a project. They offer more flexibility in design and size and can be tailored to specific needs and preferences.

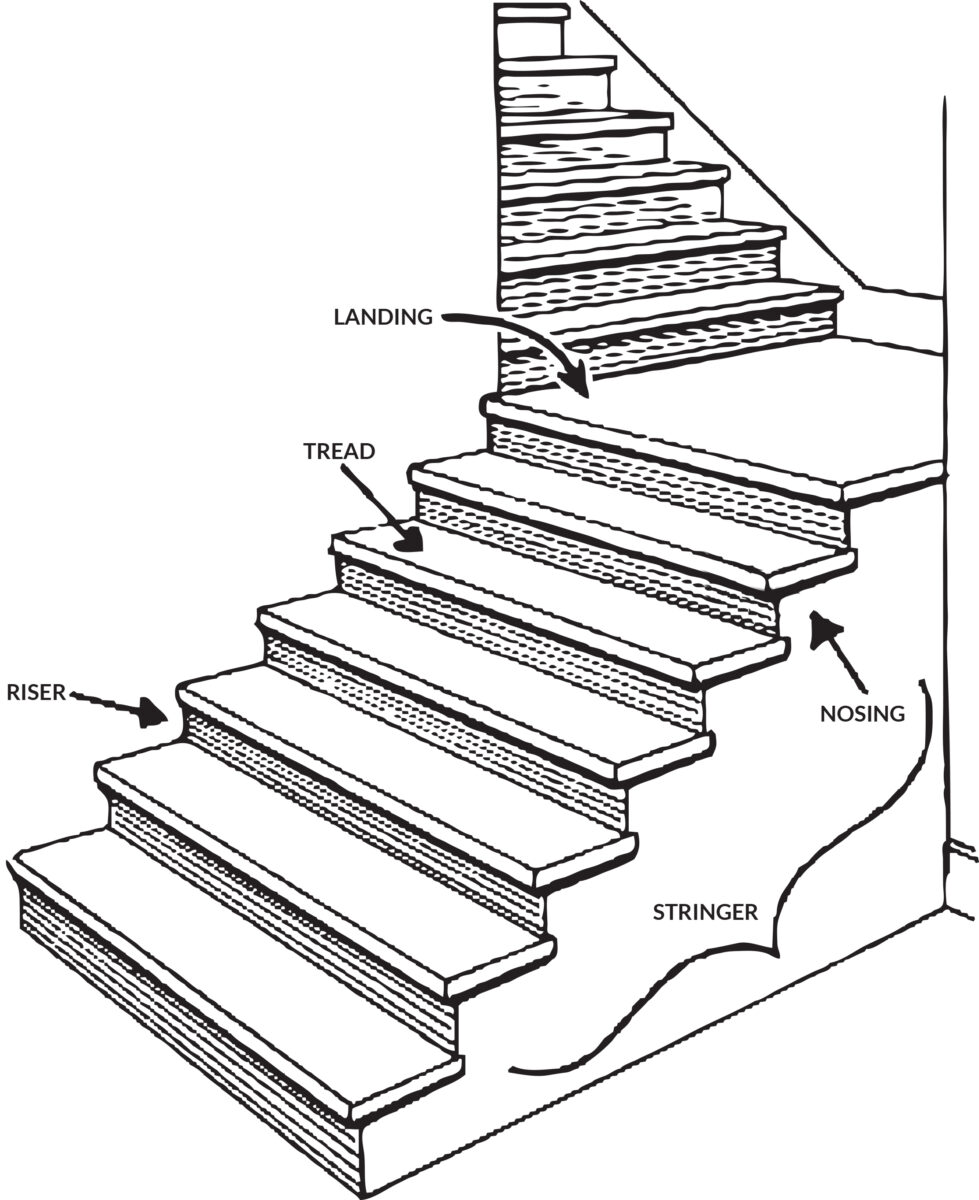

Components of a Stair Package

Delving into the components of a staircase provides insight into its structural elements and empowers you with a deeper understanding of the design options available. By familiarizing yourself with each part of the staircase, you gain clarity on how these elements can be tailored to suit your design preferences and functional requirements. Some key components of a stair package include:

- Stair treads: The horizontal surface of each step.

- Risers: The vertical surface between each step.

- Stringers: The structural support that runs along the length of the stair and supports the treads and risers.

- Landings: The flat platform located at the top, bottom, or intermediate point where the stairs change direction and/or a transition area between two sets of stairs or between a flight of stairs and a door or hallway.

- Handrails: The railing that runs along the side of the stairs for safety and support.

- Balusters: The vertical posts that support the handrail.

Custom Stair Packages

Choosing a custom stair package brings design ideas to life, creating spaces that uniquely reflect your style. From the smallest details to the overall look, each part should be carefully crafted to blend beauty with practicality. Getting a quote for custom stair package kick-starts the process, opening discussions to ensure everything matches your vision perfectly. Knowing what you want, and need is a crucial part of obtaining an accurate estimate.

Some of the things to consider when defining stair project requirements:

- The type of stringer configuration you have (e.g., closed, open on the left or right, mono-stringer, etc.).

- The number of treads required and the associated dimensions.

- The number of risers required and the associated dimensions.

- Whether or not you need nosings at intermediate landings or at the top of stairs.

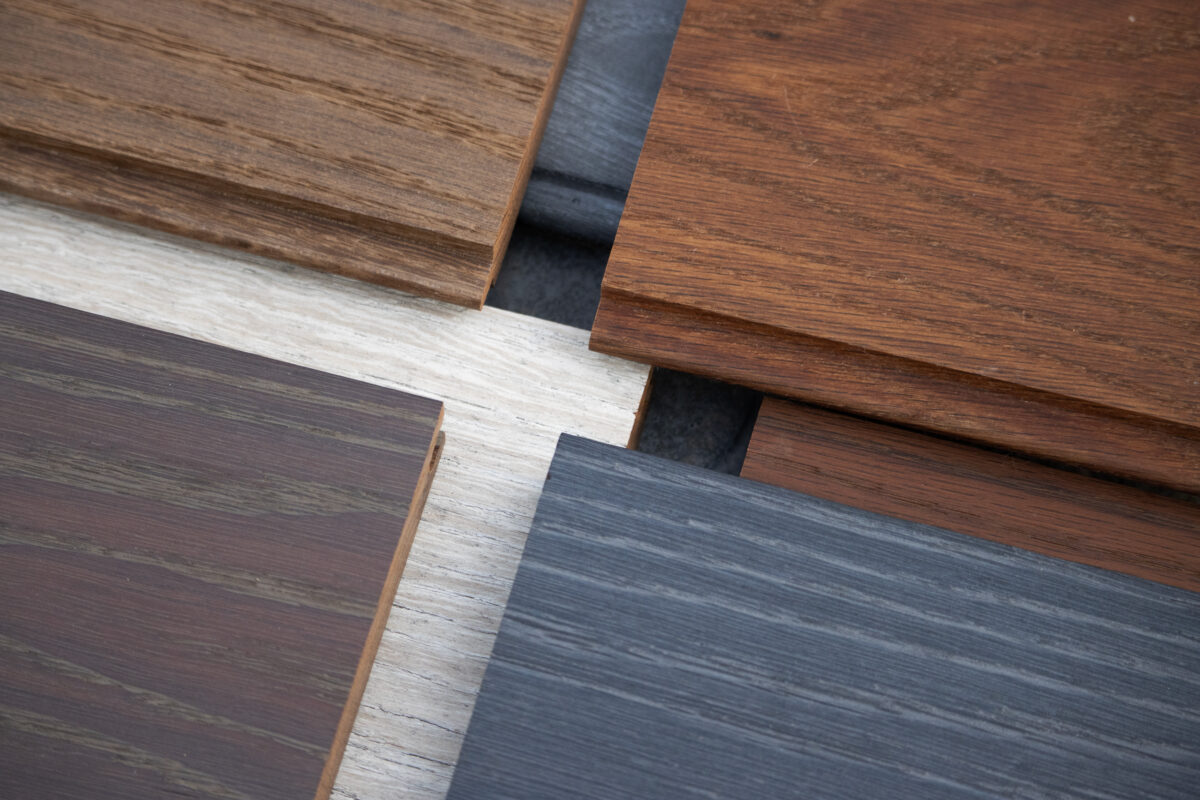

- The product you want for the stairs and accompanying parts to match (see floor offerings).

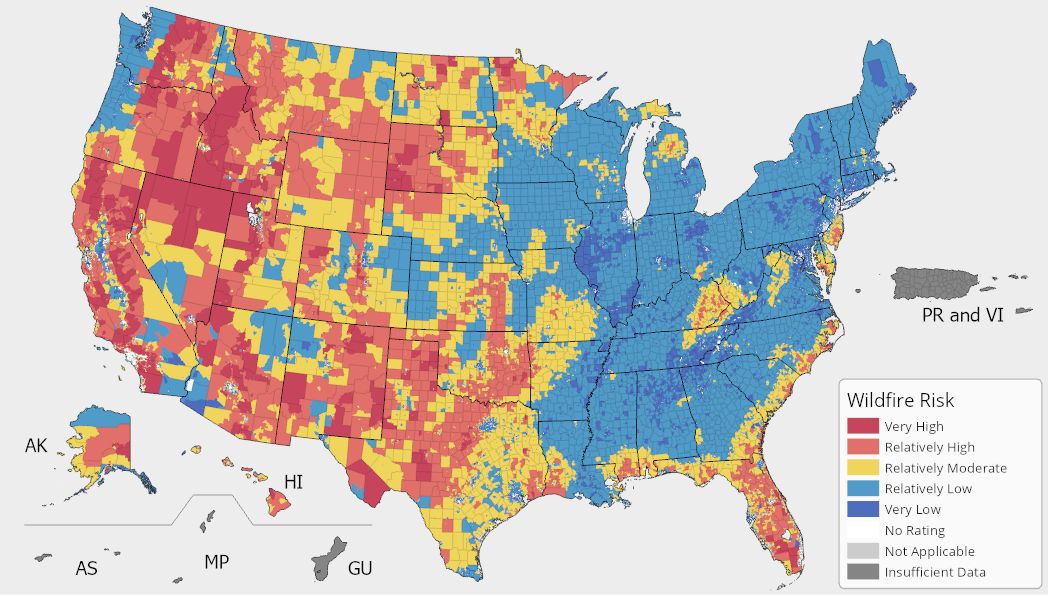

- Any special requirements you might have (e.g., ADA compliance).

Understanding the various options and project requirements is key to seamlessly integrating stair packages into your project. It is imperative to create and review architectural blueprints, measurements, and specifications. Any discrepancies could result in erroneous quotes and potential setbacks to project timelines. Working with a designer, providing precise details on the stairs, and outlining project needs early can help facilitate the provision of a more accurate and prompt quotation.

reSAWN TIMBER co. offers high-quality custom stair components and custom-built stair packages based on project needs. We provide an array of profiles for treads, risers, nosings, reducers, thresholds/saddles, wall bases, T-molding, and other essential trim offerings. From modern marvels to timeless classics, our diverse profile offering, and meticulous craftsmanship promise to transform vision into reality. Our goal is to provide bespoke solutions that enhance the aesthetic appeal of a project while ensuring durability and functionality, tailored precisely to specifications.